Welding

Welding

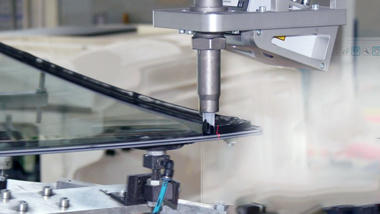

Laser Welding Laser welding is a non-impact, vibration-free welding method, and its welding strength is even higher than that of the raw material. Adjustable material welding depth, can weld complex three-dimensional shape welding wire. It can be applied to the welding of parts with a wide range of sizes and can be flexibly applied to various special systems in the production line. View Product >

Hot Plate Welding Under stable welding conditions, use high temperature and pressure to heat the welding surfaces of the two hot-melt plastics, and then apply pressure in the horizontal or vertical direction to finally weld the two plastics together. According to the application of this technology and the number of products processed, the welding equipment can be designed as a semi-automatic or fully automatic production line, a fully automatic equipment for manually placing parts, a turntable system and so on.

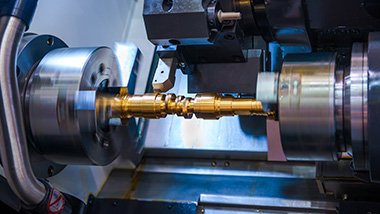

Vibration Friction Welding The hot-melt plastic is melted by friction on the contact surface to ensure high welding strength. It is suitable for almost all plastic materials and various products, especially for large workpieces. The flexible production system provides the shortest production cycle and the possibility of quick die change. Simple operation, minimal maintenance costs, and safest operation control ensure the lowest unit price. Friction welding equipment can also be extended to use non-contact infrared preheating. This technology can be applied to the automotive industry.

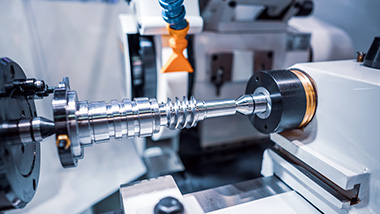

Standard Ultrasonic Welding This process can shorten the time and reduce the cost. Today, this process has its irreplaceable characteristics. For hot-melt plastic workpieces, such as tensile, waterproof, and appearance requirements, ultrasonic welding must still be used.

Non-standard Ultrasonic Welding According to different types of welding requirements, various types of ultrasonic generators and models can be provided. When the ultrasonic welding process is applied to large and complex workpieces, special machines need to be designed for production. In the current market, the first application of non-standard ultrasonic design is the automotive industry. The three major sectors in the automotive industry, instrument panels, door panels, bumpers, and special aircraft are indispensable.